Hardware: motors

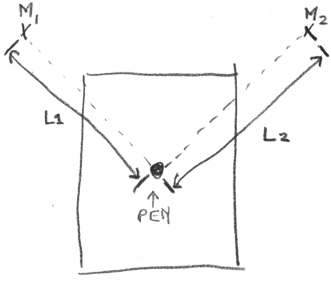

How does a bipod work?

M1 and M2 are two motors, fixed to the wall. The idea is that L1 and L2,

the distances between the motors and the pen,

can be modified by letting the motors actuate on the belts.

By varying L1 and L2, the pen can be moved to almost any

coordinate of the whiteboard.

Ok, what do we need to put this contraption together? First of all, we need an motor-assembly that's able to precisely move the belts. Secondly, we need a belt that does not slip: a slipping belt would introduce an offset in the position of the pen which could break the whole system, or at least result in pen stripes on the piece of wall next to the whiteboard.I decided that something like a teethed rubber belt and some kind of stepper motor would be ideal. Now, where to get that?

My first idea was to open up an old inkjet printer: the carriage in these devices usually is moved by a teeth belt. Unfortunately, the motors that drive these things usually are DC-motors, which have no way of precisely controlling them without some feedback of a sort, and I wasn't planning on implementing that. My second idea was to open up a flatbed scanner, and lo and behold, it contained exactly what I needed: a nice and precise stepper motor plus some gears to slow it down, a nice and long teeth belt and even a driver for the stepper motor. I bought a second scanner (actually, integrated inkjet/scanner) for ten bucks and got to work.

![]()

One of my victims: you can see the teeth belt here. Some (older) scanners use

a piece of metal wire to pull the scanner head; unfortunately we can't use these

types.

![]()

A few moments later, ehis is what remained. The motor assembly is a nice integral piece

which can be directly lifted off the carcass of the old scanner/printer-combo.

![]()

And when tied to the ceiling, everything looks like this.